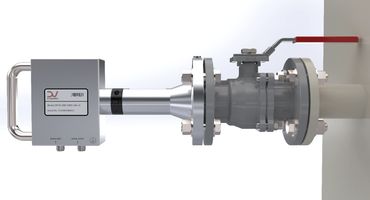

UHF Drain Valve Sensor

A UHF drain valve sensor is a non-intrusive device used to detect partial discharge (PD) activity inside oil-filled power transformers. It is installed at the transformer's drain valve, allowing electromagnetic signals from PD events to be captured externally without opening the tank.

Features

Non-Intrusive Installation

Oil-Tight and Pressure-Sealed Design

Non-Intrusive Installation

The sensor is mounted externally at the transformer's oil drain valve, requiring no internal modification or disassembly. This allows for safe and convenient retrofitting on in-service transformers without draining oil or opening the tank.

UHF Detection Capability

Oil-Tight and Pressure-Sealed Design

Non-Intrusive Installation

It detects high-frequency electromagnetic signals in the UHF range (typically 300 MHz to 2.0 GHz), which are characteristic of partial discharge events. This wide bandwidth improves sensitivity and helps distinguish PD from external noise.

Oil-Tight and Pressure-Sealed Design

Oil-Tight and Pressure-Sealed Design

Oil-Tight and Pressure-Sealed Design

The sensor is designed with robust sealing to maintain the transformer's oil integrity and pressure boundary. It uses specialized gaskets and flanges to ensure safe operation even under high oil pressure conditions.

High Sensitivity

Compatible with Online Monitoring Systems

Oil-Tight and Pressure-Sealed Design

Optimized antenna design and low-noise performance enable the sensor to detect very low-level PD signals, even from deep within the transformer tank. This enhances the ability to detect early-stage insulation defects.

EMI-Resistant Construction

Compatible with Online Monitoring Systems

Compatible with Online Monitoring Systems

The sensor is designed to operate in high-voltage environments with strong electromagnetic interference (EMI). Shielded cabling and grounded housings reduce the risk of false PD readings due to external noise sources.

Compatible with Online Monitoring Systems

Compatible with Online Monitoring Systems

Compatible with Online Monitoring Systems

It can be easily integrated into permanent PD monitoring systems. The sensor provides a standard RF output (N-type connector) for continuous or periodic diagnostics.

Ordering Code

Gallery

Specifications

Downloads

DIAGNOVOLT

Copyright © 2020-2025 DIAGNOVOLT- All Rights Reserved.